Custom Jewelry Manufacturing: China vs. Thailand

China’s Custom Jewelry Manufacturing

Advantages

China leads global jewelry production due to its scale and affordability. Key strengths include:

1.Cost Efficiency: Low labor costs (30–50% less than Thailand) and access to materials like stainless steel, brass, gold, and synthetic gems reduce production costs by up to 40%.

2.OEM/ODM Expertise: Factories offer Original Equipment Manufacturing (OEM) for custom designs and Original Design Manufacturing (ODM) with pre-designed catalogs, ideal for fast-fashion brands.

3.Advanced Technology: CAD software, 3D printing, and automated lines ensure precision.factories produce 10,000+ units daily with minimal errors.

4.Material Diversity: From jade to lab-grown diamonds, China’s supply chain supports varied designs, catering to mass-market and luxury needs.

5.Scalability: Factories handle large orders (e.g., 100,000 units), perfect for global retailers.

6.Innovation: Investments in AI-driven design and eco-friendly plating (e.g., nickel-free) align with 2025 trends.

Challenges

● High MOQs: Minimums of 500–1000+ pieces deter small brands.

● Quality Variability: ISO 9001 compliance varies; subpar factories risk defects.

● Lead Times: Custom orders may take 6–8 weeks due to logistics.

● Communication: Language barriers can complicate design specs.

Our key advantages directly address these needs:

● Cost Efficiency: Leverage our low production costs—up to 40% less—and access to a wide range of materials, from stainless steel to lab-grown diamonds.

● Expertise & Technology: With advanced CAD, 3D printing, and OEM/ODM capabilities, we deliver precise, custom designs at scale, producing over 10,000 units daily.

● Innovation: We stay ahead of trends with AI-driven design and eco-friendly options like nickel-free plating.

Thailand’s Custom Jewelry Manufacturing

Advantages

Thailand excels in artisanal craftsmanship. Key strengths:

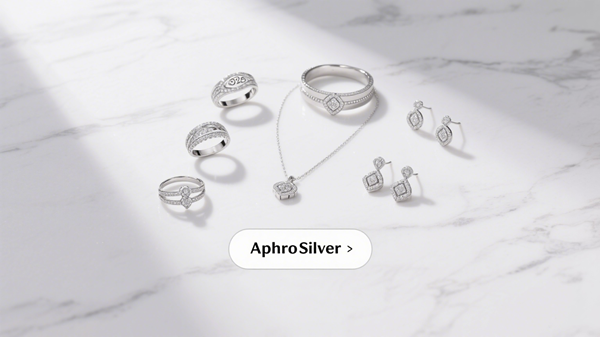

1.Craftsmanship: Centuries-old expertise in 925 sterling silver and gemstones, as seen in AphroSilver’s premium designs, ensures superior quality.

2.Low MOQs: Orders as low as 50–100 pieces suit small brands.

3.Customization: Handcrafted designs with modern tools like laser engraving offer bespoke solutions.

4.Ethical Sourcing: Responsible gem and metal sourcing aligns with sustainability.

5.Logistics: Efficient exports ensure 2–4 week lead times.

Challenges

● Cost: Labor costs are 20–30% higher than China.

● Scale: Limited for mass production (e.g., 10,000+ units).

● Materials: Focus on silver and gems limits variety.

Comparison: China vs. Thailand

| Factor | China | Thailand |

|---|---|---|

| Cost | Lower labor/materials | Higher but competitive |

| MOQs | High (500–1000+) | Low (50–100) |

| Craftsmanship | Tech-driven, mass production | |

| Customization | OEM/ODM, catalog-based | Bespoke, small-batch |

| Materials | Wide variety | Silver, gems focus |

| Lead Times | Longer (6–8 weeks) | Shorter (2–4 weeks) |

| Sustainability | Varies | Ethical focus |

| Logistics | Large-scale, potential delays | Efficient exports |

Why Choose AphroSilver?

AphroSilver, based in China, combines traditional craftsmanship with modern design to produce 925 sterling silver jewelry. Their low MOQs, ethical sourcing, and bespoke capabilities make them ideal for premium brands. While the industry faces challenges like high MOQs and communication barriers, we offer flexible solutions and clear communication to ensure your vision is realized perfectly. Partner with us for scalable, high-quality, and affordable jewelry manufacturing.

Tips for Choosing

1.Define goals: cost (China) or quality (Thailand)

2.Verify certifications (ISO 9001, RJC)

3.Request samples

4.Align MOQs with budget

5.Partner with experts like AphroSilver

Conclusion

China offers cost-effective, scalable production, while China, via brands like AphroSilver, excels in artisanal quality and flexibility. Choose based on your needs. Visit AphroSilver for premium 925 sterling silver designs.

Jewelry Wholesaler One Stop Solution or download our sourcing guide.

Trust Signals

- Contact Contact Us for certifications.